The Volta Annual Battery Report Reveals the Limitations of Today’s Battery Solutions

Volta Foundation released the Annual Battery Report 2022, summarizing the most significant trends in the industry and providing an unbiased and comprehensive overview of the latest developments in battery research, policy, and the business landscape.

Let’s start with the good news for every company involved: The pie is growing. In particular, investment in battery management systems (BMS) and battery intelligence is one of the sub-sectors that experienced the most growth in 2022 compared with the year prior.

This trend is encouraging because more companies realize that pumping out more batteries cheaper isn’t enough to maximize the benefits of electrification. The key to decarbonization without impeding progress will depend on our ability to use resources efficiently — and analytics will open up new ways to do so.

However, some of the report’s analyses and projections are based on assumptions of what existing battery technologies can do. And our current path to electrification is full of technical limitations. We can solve some of these challenges cost-effectively by considering “what batteries can do” differently.

This article examines a few gaps and discusses how data-driven, software-defined batteries (SDBs) can make the concerns in some critical areas an (almost) non-issue, thereby reducing R&D costs while accelerating product development cycles.

The Groundwork: Industry Player Categories

Pages 20 and 21 of the Volta Report listed six main categories in the battery economy: raw mineral mining and refining, materials processing, component manufacturing, cell and pack manufacturing, battery data and EV/ESS application, and recycling and second life.

While there is a battery data category, none of the companies listed has an industry-wide approach. They have only devised slightly more sophisticated ways to use data analytics in their products. Nobody has yet created a solution that taps into the pooling advantage so businesses can reap the benefits of data insights to achieve a catalytic effect across sectors.

We need a mindset shift. Let’s step back and look at the airline and IT industries.

Until the 1980s, an airline business focused on hardware — building and operating planes. Deregulation introduced a business opportunity for increasing cost-efficiency. Software and data analytics entered the picture to enable dynamic pricing, and optimize resource scheduling, to name a few. The industry's growth rate hockey-sticked.

The same happened when the IT industry transitioned from a hardware-focused sector to a software-dominated landscape. For example, Microsoft nailed the commonalities among tasks performed by office workers and created software to facilitate them. MS Office delivers universal benefits without addressing specific end-user requirements.

The introduction of software solutions is where the curve hockey-sticks.

We’re at this inflection point with battery technologies. Most companies that use battery data are only concerned with how it applies to their products. But data analytics isn’t about EVs or specific equipment alone. We need a solution that leverages universally accepted principles to transcend industries so we can leverage data to catalyze electrification at scale.

A battery operating system that supports software-defined batteries can provide a platform to spread universal benefits across industries. It can accelerate the growth of the battery economy and make electrification sustainable and profitable.

Battery Characteristics and Application Landscape

Page 50 of the Volta Report listed the top three key metrics for six industries that use battery solutions: aviation, transportation, handheld equipment, power grid medical, and defense.

Today’s equipment manufacturers must tailor their battery solutions to optimize those metrics for individual applications at the product design stage — the one-off nature translates into high R&D costs and lengthy development cycles.

On the other hand, software-defined batteries make custom-designing batter solutions per specific metrics unnecessary. Product builders and operators can choose from a library of functionalities and adjust a battery pack’s behaviors on the fly on a computer screen to meet operational criteria at any given moment.

This capability vastly reduces the resources required to create custom battery solutions for any application, allowing small and medium enterprises to develop innovative solutions and throw their hats into the electrification ring.

But R&D is just the tip of the iceberg. The ability to select a battery pack’s characteristics from a universal feature set at the last mile means equipment manufacturers don’t have to stock their shelves with hundreds of battery pack varieties.

Plus, business and regulatory requirements change. The flexibility means that product builders don’t have to predict how an expensive asset (e.g., large industrial equipment) needs to perform years from now, design the battery pack against those requirements, and hope that they guessed correctly.

For example, Tanktwo Smartpak’s modularity, adaptability, and configurability mean builders and operators only need to stock one type of battery module to service multiple products — vastly simplifying inventory management and improving cash flow.

Battery Chemistries and Hybrid Chemistry Architectures

The Volta Report provides a detailed comparison of various battery chemistries. As discussed above, different applications have different criteria. Today’s battery engineers must decide what key metrics to hit and select the battery chemistries to meet the requirements.

The lack of horizontal applicability means if criteria and requirements change, product builders and manufacturers must go back to the drawing board to redesign their battery solutions and possibly the equipment to go around it.

Again, SDBs render this hurdle a non-issue. The Tanktwo Battery Operating System (TBOS) allows product builders to mix and match cells of different battery chemistries. The software then activates the appropriate cells to achieve the behaviors required at any given moment.

The flexibility to use different cells of any age also helps shield companies from supply chain fluctuations while benefiting from the commodification of batteries.

The report further delves into the concept of hybrid chemistry architecture. Product builders can compensate for performance, costs, and longevity shortcomings by combining cells of different chemistries.

The report explores the pros and cons: While hybrid battery packs show promise for reducing costs by using low-cost cathode materials, it adds complexity to electrical architecture and BMS design. But the complexity is only an issue if you have to reinvent the wheel every time.

SDB technology complements the concept of hybrid chemistry architecture because using different battery chemistries can further increase the range and capabilities of a battery pack. Meanwhile, TBOS gives operators granular control to tap into the right chemistry mix at the right time — changing battery behaviors dynamically based on operational profile.

Resource Usage, Stationary Storage, and Alternative Chemistry Development

A few sections in the Volta Battery Report touch upon the need for more efficient use of resources, the environmental impact of current battery solutions, and the race to develop alternative battery chemistries to reduce our reliance on lithium.

On page 74, the report suggests using smaller battery packs to minimize costs for OEMs, raw material usage, and carbon dioxide emissions. But a small battery pack is limiting, and many people won’t choose it due to range anxiety. Plus, smaller packs can’t solve the electrification challenges faced by EV fleets and shared mobility solutions.

Our string cell ecosystem, built on the concept of SDBs and TBOS, allows users to put the right amount of power into an EV for a given trip without carrying extra weight. Plus, range anxiety only exists if you must leave a vehicle at the charging station for hours. The ability to swab used cells with freshly-charged ones in minutes makes it a non-issue.

Meanwhile, the increase in stationary storage needs to support renewable energy sources and the rise in raw material prices will drive companies to seek lithium alternatives in battery manufacturing.

In particular, lithium-ion batteries aren’t cost-competitive in providing multi-day storage necessary for stationary applications to improve the reliability of systems that use wind and solar power. Plus, raging lithium fires pose significant challenges in system engineering, emergency responses, and community buy-in.

Moreover, the high environmental and social costs of lithium mining and processing are putting more pressure on corporations to seek accessible and environmentally-friendly materials to replace cobalt and lithium.

There’s a lot to unpack here, but they’re all related. And you guessed it — SDBs can address them in one fell swoop.

There will be a shift to alternative battery chemistries in the near future to reduce costs, meet reliability and safety requirements, and/or lower the total cost of ownership. But adoption can be an uphill battle because current battery solutions aren’t chemistry-agnostic. Battery packs must be replaced, while equipment design may require a complete overhaul.

On the other hand, SDB systems future-proof equipment and battery solutions because of their modularity and ability to use cells of any chemistries. Operators can just swab out old cells with new ones, making the transition as simple as a routine maintenance event.

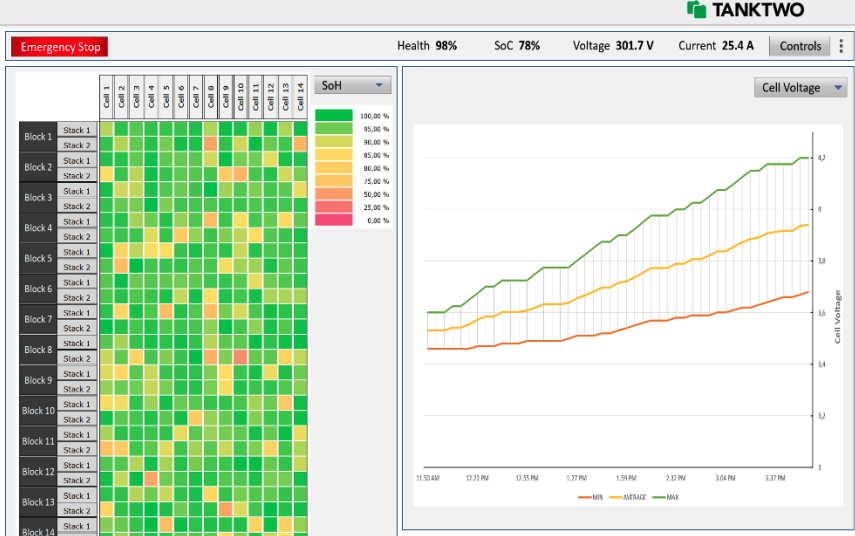

Also, TBOS offers advanced yellow-flagging and data analytics capacities to identify and disable cells that are failing or at risk of having thermal runaway events without impacting the battery pack's performance. These features offer safety and cost-saving advantages without compromising each other.

The ability to automatically deactivate problematic cells can dramatically improve the safety of any battery-operated system, whether stationary or mobile. Meanwhile, companies can replace expensive and wasteful just-in-case maintenance with a just-in-time approach, so only aging and faulty cells are removed and replaced.

Wrapping It Up: Battery Informatics Is the Future

In one of the final pages concluding the industry section, the Volta Report stated that analytics is essential for tracking batteries through their lifecycle. It also provides examples of how a data-driven approach can support research, manufacturing, field operations, and second-life usage.

We need the tools to put the pieces together.

SDBs built on TBOS can realize the impacts stated in the report while mitigating various existing challenges and limitations. The universality of our system efficiently standardizes and normalizes data for analytics to facilitate research and manufacturing.

Meanwhile, TBOS not only collects and reacts to data. Our predictive analytics capabilities and real-time communication with battery cells allow them to optimize field operations minute-to-minute proactively. Lastly, TBOS collects data to determine the state of health (SoH) of every cell in a system. The information is essential for cost-efficient second-life applications.

Future-proofing battery solutions

We don’t have a magic 8 ball to tell us what will happen in the battery industry, government regulations, and sustainability conversations. Instead of putting all our eggs in one basket, we make our technology application agnostic.

SDBs can pivot on a dime (e.g., think AWS, where the server can distribute cat videos one day and model climate change the next) instead of being built for a specific function (like a crypto mining center — when crypto’s value went down, GPUs flooded the market.)

Like how MS-DOS and Windows operating systems laid the foundation for personal computing to thrive in businesses, TBOS has the lasting power to become the backbone of the electrification ecosystem — pushing the global battery economy to its logical conclusion: Providing a platform for software and services to create value we can’t even imagine right now.